Production

Products under the trademark Trapeza have been produced since 1998 by Novosibirsk Food Factory.

The factory packs and produces the following:

- Classic spices such black and red pepper, cloves, nutmeg and many other.

- Seasoning blends for various dishes.

- Meal makers, i. e. ready-made mixes for cooking various dishes.

- Breadcrumbs for meat, fish, and poultry.

- Culinary additives such as citric acid, starch, and vanillin.

- Fruit and berry kissels and jellies.

- Mixes for making sauces, gravies, and marinades.

- Ice cream mix powders.

Trapeza products are known throughout the whole Russia, in neighboring countries and beyond, and may be found both in convenience stores and in the federal retail chains.

Our strategy is focused on quality!

Quality confirmed by independent assessment

Trapeza brand was created with such values in mind as the quality, natural products, environmental friendliness, and availability to a wide range of customers.

Many food manufacturers claim the quality of their products but few can confirm it with independent assessments. We can! Since 2007, our production has been certified according tointernational standards: ISO 9001 for Quality Management System and ISO 22000 for Food Safety , which develop the principles of the HACCP system. We were one of the first in Russia to receive the ISO 22000 certification, and the first to undergo recertification three years later and extend the validity of the certificate for three years more. In 2016, the factory reached a fundamentally new level — it successfull renewed its FSSC 22000 Food Safety System Certification.

Quality is guaranteed by state-of-the-art infrastructure, cleanliness and control.

As the famous saying goes, cleanliness is next to godliness. A state-of-the-art infrastructure was created in the factory that ensures the world-class level of its production environment both in terms of sanitation and safety of food production, and in terms of ecology, ergonomics, and comfort. The factory is located in an ecologically clean suburban area of Novosibirsk. Energy efficient technologies and advanced machinery have made it possible tosignificantly reduce operating costs and optimize the cost of production which certainly had an impact on the price of the final product. GMP and HACCP requirements, generally accepted standards for food production, laid the foundation and served as the guidelines for the creation of the factory and were successfully implemented.

We pay particular attention to selection and storage of raw materials including careful selection of suppliers, strict incoming inspection, quarantine zones, and a dedicated storage. Our warehouse complex complies with the necessary storage requirements for both raw materials and finished products such as constant temperature and humidity, no pests and no cross-contamination. Eco-friendly handling machinery streamlines all warehouseoperations and helpsto handle the feedstock with care. Spices and seasonings retain their full flavor.

Laboratory control ensures high-quality raw materials in and finished products that meet all the standards out.

Our own technology laboratory tests new products quickly which speeds up the process of

developing new lines of products. Recipes of our seasoning blends have been developed by leading Russian food technologists and passed long-term tests. Tastings with different groups of consumers make it pos sible to take into account different tastes and preferences. And the preliminary search for competitive advantages leads to the creation of unique products. Launching new product lines helps to keep customers engaged. This is how we create products that meet the needs of customers to the maximum extent.

The products are packed into foiled bags with enhanced barrier properties. Such packages are airtight, do not allow moisture and essential oils to pass through (and thus prevent rancidity of the contents, oi

ling of the packages and thinning of aromas), and do not fade. Our constant search for the best designs helps us to offer colorful, clear packaging. The balance of the cost of materials, their barrier properties, and color printing allows us to compete with foreign brands on store shelves.

Raw materials go through additional decontamination and get sieved, calibrated and packaged. The use of high-tech Italian machinery allows us to minimize manufacturing costs and the risk of product contamination while maintaining the quality of the ingredients. And the reliability of the machinery ensures a high filling speed and uninterrupted operation of the lines.

Each package contains recommendations on the use and a recipe. Consumers may call the phone number indicated on the package or send a letter to the quality department that collects and analyzes suggestions and comments from consumers. Traceability helps to ensure that every claim is investigated promptly.

History

Establishment of OOO Novisibirskbakaleya. Development of business contacts in the wholesale food market. Stable growth of the company. Beginning of work with the Spices and Seasonings product group.

Working on a project for the production of packaged food concentrates, road map development, market research.

Birth of Trapeza trademark that later becomes an umbrella brand for all of our products. Launch of Novosibirsk Food Factory. Purchase of machinery in Italy, installation of the first line and release of the first product — Ground Black Pepper.

Significant expansion of our product portfolio. First participation in international exhibitions. At the Prodsib-99 exhibition, the products of the Novosibirsk Food Factory are awarded a small gold medal for the wide range of spices. From 1999 to 2003, products under the trademark Trapeza are annually awarded gold, silver, and bronze medals at WorldFood, Prodexpo, Prodsib exhibitions as well as numerous regional exhibition fairs.

We work on recipes and launch manufacturing of seasoning blends for various foods including meat, fish, poultry, ground meat, etc.

We work on recipes and launch manufacturing of instant kissel drinks. We start to export our products to the USA, Germany, and Israel. We open an office in Moscow.

We start to supply Trapeza products to the leading Russian retail chains: Ramstore, Pyaterochka, Auchan. As of the end of 2002 (according to the Russian Public Opinion Research Center), Trapeza is one of the leading Russian brands on the spice and seasoning market in Moscow and St. Petersburg

.

Trapeza products successfully pass expert review at the Kremlyovsky food factory and start to be supplied to the Kremlin canteens. Trapeza has partners in all major cities of Russia, its products are popular among both urban and rural residents. A new line of seasonings is launched into production. A new type of packaging made of multilayer combined materials is integrated which makes it possible to increase the barrier quality of the packaging and improve its appearance.

Trapeza spices and seasonings win in the 100 Best Goods of Russia 2004 competition. As a result of the research of the Russian food industry, Ernst & Young ranks Trapeza among the leading companies in the soups, spices and seasonings market.

Launch of new technological lines. Launch of new product groups: breadcrumbs and jellies. Trapeza kissel drinks become diploma winners of the 100 Best Goods of Russia 2005 competition.

Novosibirsk Food Factory implements a quality and safety management system for food products and gets successfully audited by the international certification body of SGS (Switzerland) for compliance with international standards: ISO 9001:2000 Quality Management System and ISO 22000:2005: Food Safety Management System.. The purpose of implementing these standards is the controlled and stable release of safe and high-quality food products. Certificates are issued for three years and are to be confirmed every year byindependent inspections.

Launch of kissel drinks made from natural juice extracts. Launch of line for automatic packaging

of bay leaves into transparent multilayer plastic bags. Launch of 10 g packs of selected bay leaves. Now one can see the quality of every leaf before the purchase.

Annual inspection audits by SGS confirm the compliance of our management systems with the requirements of the standards.

The factory performs recertification of the product quality and safety management system implemented in accordance with international standards ISO 9001:2008 and ISO 22000:2005. Compliance is confirmed and certificates are extended for another three years. In 2011 and 2012, annual inspection audits by SGS confirm that our management systems comply with the standards.

Manufacturing of sauces and vegetable mixes, seasoning salts in cans, and a seasoning blend for mulled wine begins.

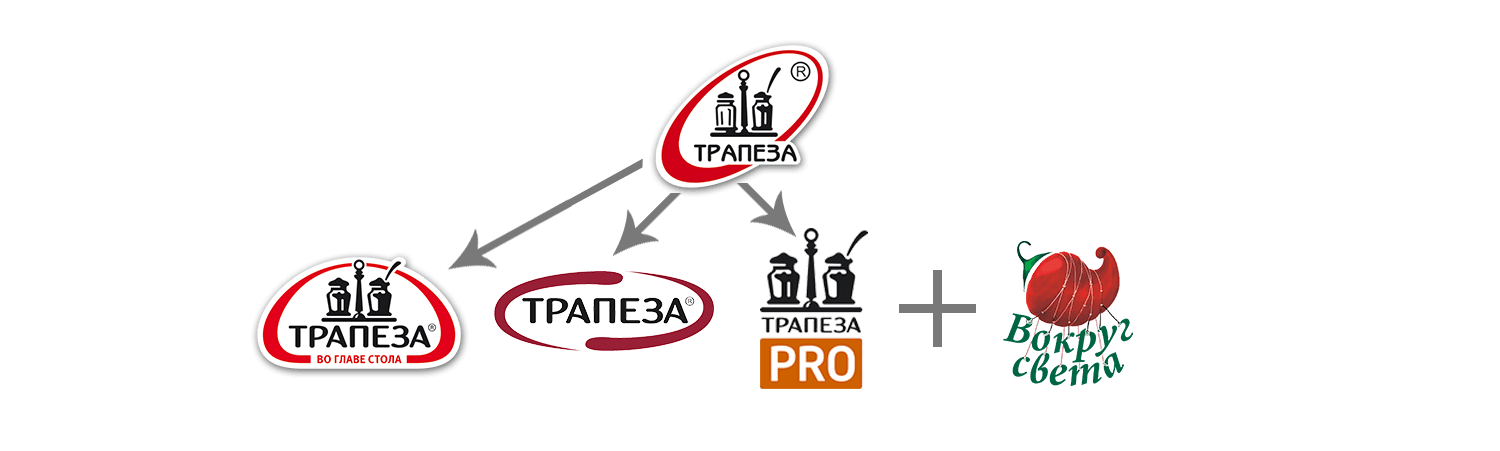

Launch of marinade mixes, spices and seasoning blends in grinders, and sea salt in cans and expansion of the range of all-purpose seasoning blends. Installation of new lines for automatic stacking of the products. Trapeza gets rebranding and new brands appear: for spices and seasonings, for kissel and jelly mixes, and for professional series.

A new brand called Vokrug Sveta (Around the World) is created for a new group of premium products. Unique lines are developed:

- Vokrug Sveta grinders with new, most delicious ingredients and the fastest grinder heads.

- Trapeza instant kissel mixes in 20 g portion packs with a unique additive – chia powder, a natural plant- based source of Omega-3 fatty acids.

- GoGoRiki kissels for kids with chia powder recommended for children starting from 3 years old by the RAMS Institute of Nutrition

At ProdEXPO-2013, Trapeza presents only new products.

Under the slogan “Bake! Soak! Decorate!”, we launch a line called Retsepty Vkusa (Flavor Recipes) that includes baking and dessert mixes.

The first 10 products of the new line are developed and launched including Trapeza Second Course meal makers, natural mixes for cooking various dishes.

A line of homemade soft ice cream mix powders is created under the Retsepty Vkusa trademark.

10 more Trapeza Second Course mixes are launched to the market.